Prospects of re-attempting VPT

In the initial stages of working on the vertical probe VPT, there was a tendency to aim too high-end materials and specifications. However, subsequent development of related technologies has progressed, allowing costs to be reduced and practicality to be improved, and it has become possible to try again by reviewing the target market and specifications.

Below, we will explain the favorable environmental conditions that have made it possible to try again, and the active change in conditions.

1. Environmental conditions have improved: Conditions are now favorable for the use of inexpensive probe materials.

In early development, iridium, a high-grade probe material that does not form oxide films, was used. However, iridium is a very expensive material. However, advances in cleaning sheet technology have made it possible to use cheaper probe materials. Rhenium tungsten has a high CCC (current carrying capacity) and excellent mechanical properties. The only drawback is that it easily forms oxide films. When an oxide film forms, the contact resistance increases, causing problems with electrical continuity testing.

Probes made of rhenium tungsten do not always cause continuity problems due to the generation of oxide films. While a contact continuity test is being performed, oxide films are unlikely to form, but after leaving the probe for a long time, such as when starting work, it is easy for oxide films to cause continuity problems.

Therefore, if you use a cleaning sheet with an oxide film removal function (optional) to remove the oxide film from the tip of the probe after leaving the probe card for a long time, such as at the start of work or after a lunch break, you will no longer need an expensive iridium probe.

![Expensive Iridium Probe → (Substitution [Significant Cost Reduction]) → Inexpensive Rhenium-Tungsten Probe + Use of Cleaning Sheet for Oxide Film Removal](./images/retry_vpt/vpt_1.png)

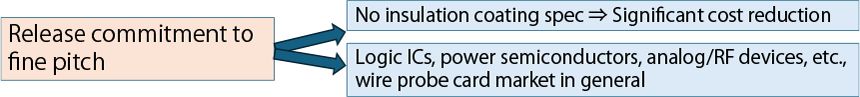

2. Actively changing the environmental conditions: Abandoning the obsession with fine pitch and developing the market by reducing costs

with fine pitch and developing the market by reducing costs In the early stages of development, we believed that we would not be able to enter the market unless we aimed for the most cutting-edge, so we aimed for cutting-edge fine pitch specifications. However, this only increased costs and made the barrier to entry even higher.

The reason for the increased costs was not only that thin probes were expensive, but also that an insulating coating was essential for Fine Pitch, which was another major factor in increasing costs.

3. Significant cost reductions using automatic pin insertion equipment and reshaping sheets

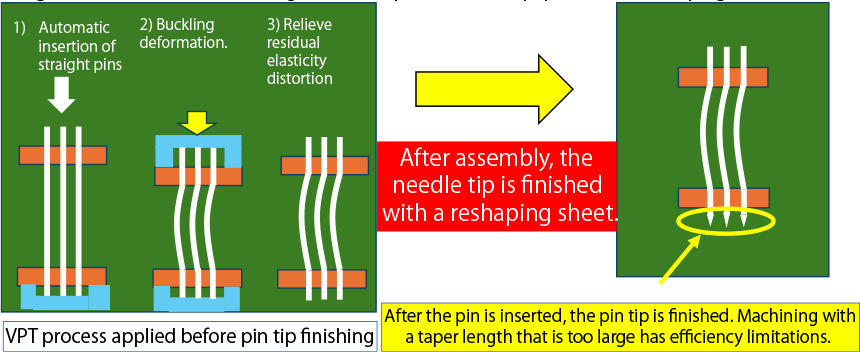

One of the features of the vertical probe VPT is the automatic pin insertion device. However, the automatic pin insertion device could not be used with conventional wire probes.

- If the pin tips are finished and then put into an automatic pin insertion device, the tips will be crushed and damaged.

- If the pin tips are not finished and inserted into a jig using an automatic pin insertion device, there is no appropriate way to process the pin tips after assembly. When using reshaping sheets, the following revolutionary construction methods are possible:

Significant cost reductions using automatic pin insertion equipment and reshaping sheets