1. Structure, size, and appearance

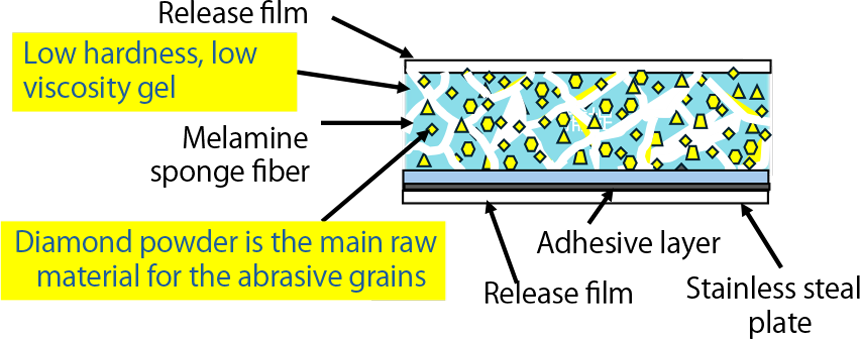

Reshaping Sheet Structure

- The structure, size, and appearance are the same as the cleaning sheet.

- The only differences are the type of gel (hardness and viscosity) and the type and content of abrasives.

- The difference is that the abrasives contain a sufficient amount of diamond powder, which has high abrasiveness and sharp cutting ability.

- Sharp diamond abrasive grains process the probe.

- The diamond abrasive grains are supported by the melamine sponge so they do not sink below the gel layer.

- The low-hardness, low-viscosity gel quickly restores the probe insertion hole, allowing continuous

2. Processing examples

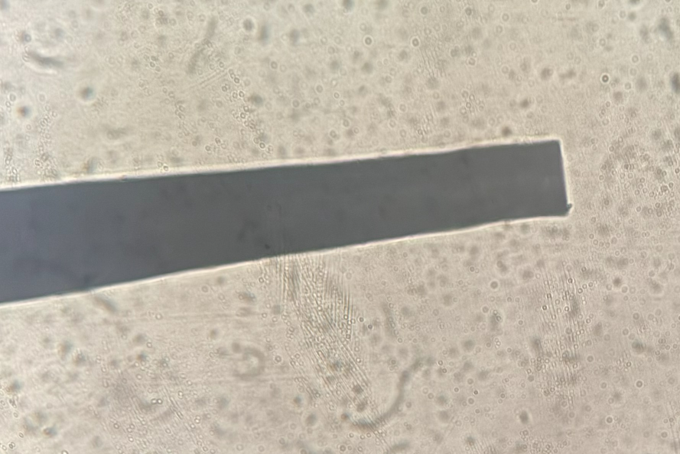

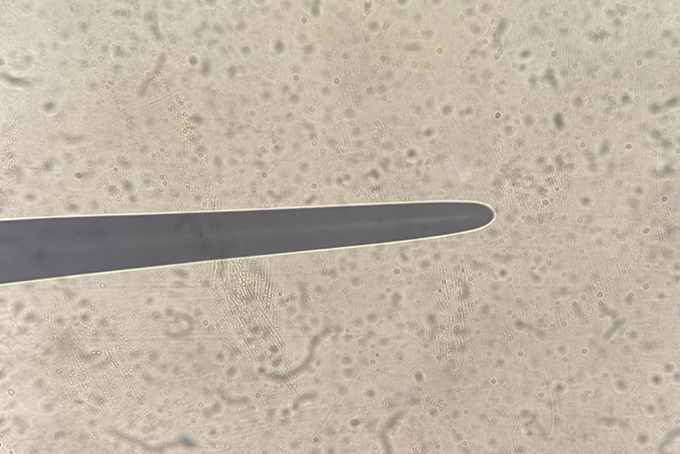

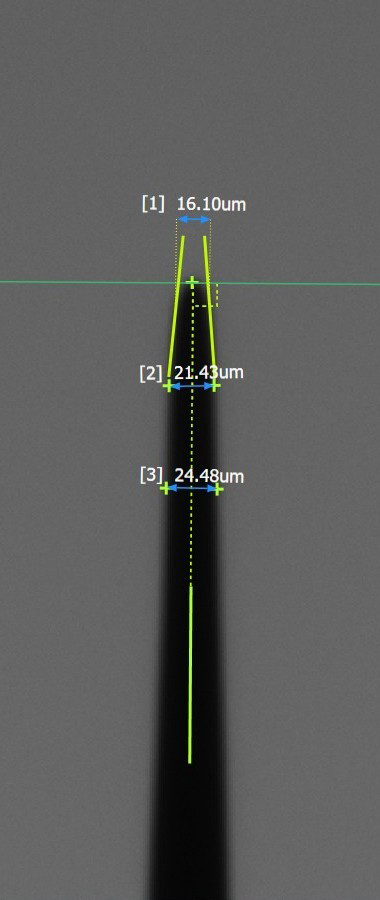

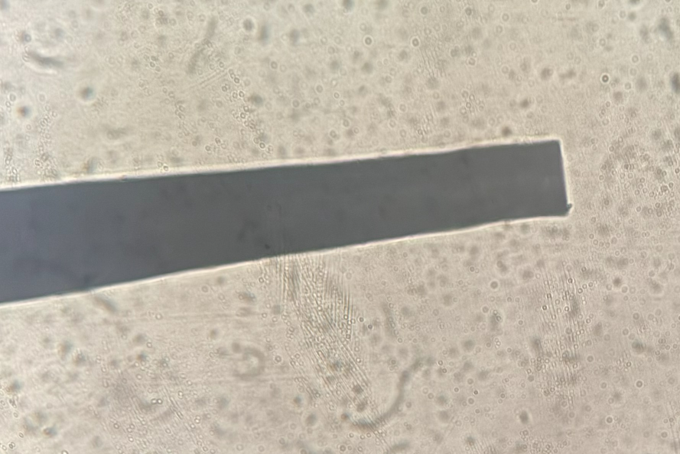

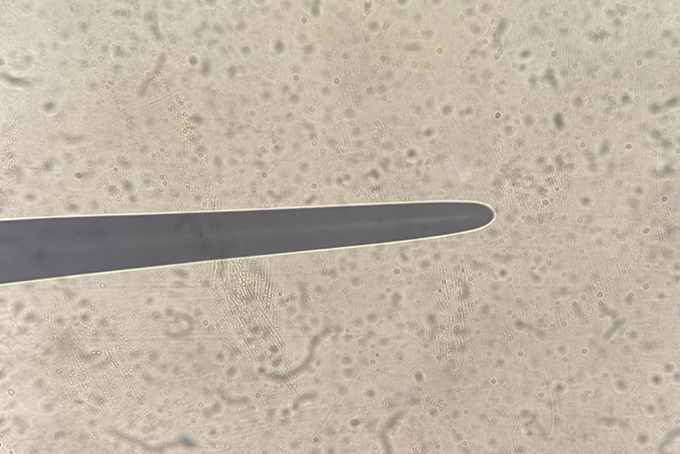

P7 probe processing exampleTransmitted image

Probe material : P7

Taper angle : 6°

Before

After

Before

After

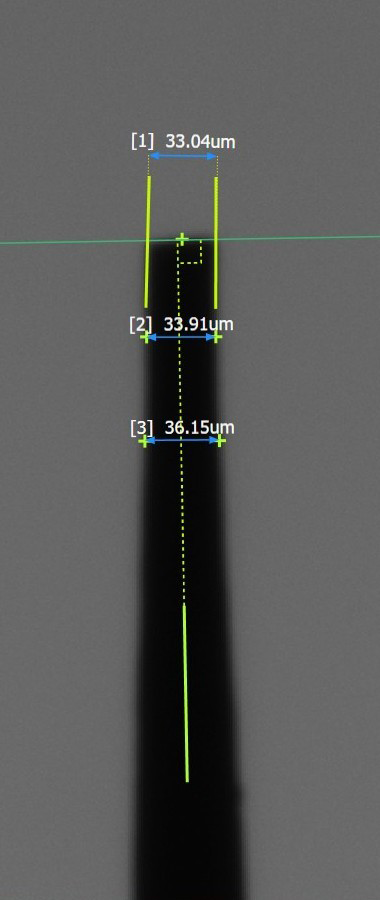

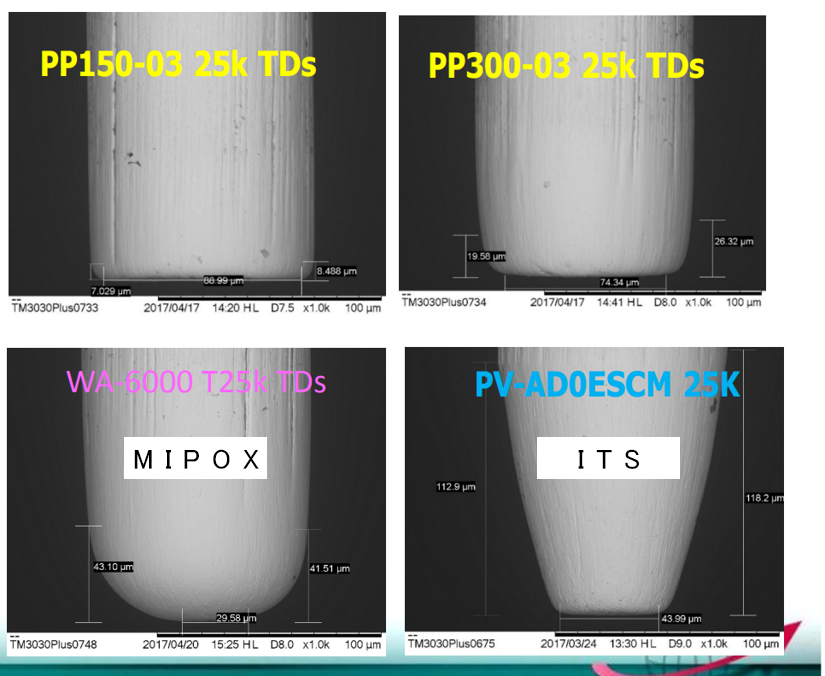

3. Comparison of processing efficiency with other companies

Before

After

In our case:

After 2,000 touchdowns, the tip diameter was halved from

33μ to 16μ. A reduction of 17μ.

(Pin diameter at base: 100μ)

Processing efficiency:

4 times or more

(It is estimated that an additional T/D of 10K or more is required to reduce the diameter from 50μ to 16μ.)

Other companies:

After 25K (25,000) touchdowns, the diameter was halved from 100μ to 50μ.

4. Comparison of seat wear with other companies

How many times can you insert probe to the same location of sheet for processing?

| ITS | Our company |

|---|---|

| Only one time | 100 times or more |

| The hole where the probe is inserted does not close, so if you insert it once, you cannot process it. You need to insert it in a different position each time. | It is a special gel that closes the hole made by the probe when the probe is removed. There is little degradation in processing ability up to 100 times. |

In other words, the amount of sheet wear is 1/100 or less compared to other companies.